- Common inbound logistics gaps

- Areas inbound management adds value

- Start a strategic inbound programme

- Proactively managing inbound freight

- Intellectual capital & customisation

- More opportunities in inbound logistics

With the right processes and visibility, companies of any size can improve the inbound segment of the supply chain. There are multiple components in an inbound programme. In this paper, we'll focus on how visibility and business processes can drive improved savings and service.

For decades, companies have focused intensively on eliminating inefficiencies and finding savings within their outbound logistics while treating inbound transportation as a necessary but secondary concern. This approach leaves substantial value on the table as many of the same process improvements that are applied to outbound transportation to save time and money actually work on inbound, too.

Common inbound logistics gaps

Transportation costs are affected by carrier acceptance rates, market volatility, order patterns and quantities. To hedge for unknown costs, suppliers often factor in a margin of error in your delivered price for inbound products. That makes it impossible to know how well suppliers are managing your transportation or for you to obtain a true cost per unit.

Lack of optimisation is another type of process gap. Sometimes, suppliers ship product to get it off their own dock, not for your benefit. And unless suppliers optimise orders and consolidate loads, they may not maximise the weight on the trucks they send to you.

Finally, delivered pricing is sometimes structured so that any reduction the supplier negotiates in freight rates adds to their margin. That gives the supplier an incentive to select lowest-cost carriers, without regard to service.

5 areas where inbound management delivers value

An effective inbound logistics program does more than just cut costs; it creates a ripple effect of positive effects across your entire supply chain. Inbound programmes can enhance processes and achieve savings through:

1. Cost control and visibility

The most immediate benefit of inbound transportation management lies in cost control and visibility. Without active management, inbound freight costs often operate as a black box, with suppliers making transportation decisions that may not align with the buyer's broader logistics strategy. By taking control of inbound transportation, companies can reduce costs through optimised routeing, carrier selection and consolidation opportunities.

For example, carrier bidding processes help identify optimal carriers and rates, while adding inbound lanes to existing outbound volumes increases total freight volumes, making businesses more attractive to carriers and potentially securing lower rates.

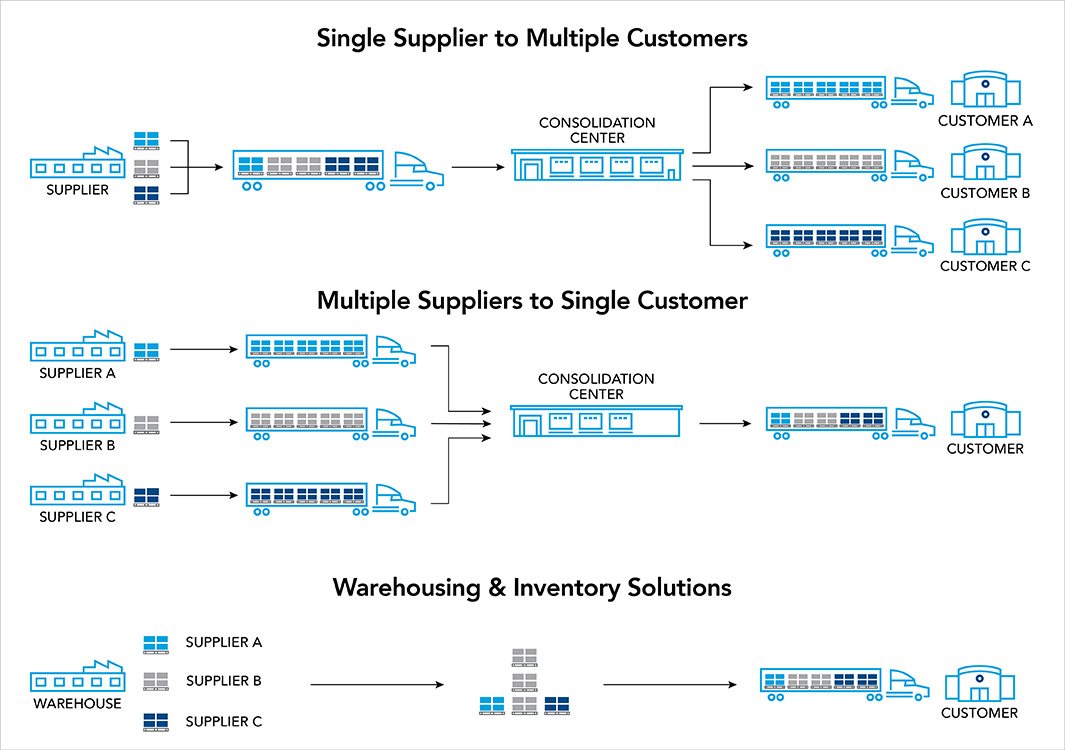

Individual orders can be optimised and grouped together across facilities to create multi-pick, single drop deliveries, while LTL loads from multiple suppliers can be consolidated into single truckloads to reduce costs and dock congestion.

Best of all, inbound management offers a deeper level of real-time visibility into the entire supply chain. After all, when you understand the true cost of moving goods from various suppliers—by SKU, case or individual item—you can make informed decisions about sourcing strategies, supplier selection and inventory positioning to enable more accurate pricing decisions and better supplier negotiations.

2. Enhanced supply chain co-ordination

By managing your own inbound transportation, you gain the ability to transform fragmented, supplier-driven logistics into a co-ordinated flow. Rather than having dozens of suppliers independently arranging deliveries, you can orchestrate deliveries to optimise receiving operations, reduce dock congestion and improve labour utilisation (see illustration below).

This co-ordination enables advanced strategies like crossdocking, where inbound materials and products move directly to outbound deliveries with minimal warehouse handling. It also facilitates better demand planning by providing accurate visibility into incoming inventory, reducing the safety stock needed to buffer against supply uncertainty.

3. Improved service levels and risk management

Because companies can establish consistent service standards, implement performance monitoring and quickly address issues, service issues are often resolved before they affect processes or customer service. Risk management can also become more sophisticated, which is particularly crucial when up against volatile transportation environments that can quickly disrupt supply chains.

4. Operational efficiency and integration

The operational benefits of inbound transportation management extend throughout the organisation. Receiving operations become more predictable and efficient when deliveries are scheduled and co-ordinated rather than arriving randomly. Warehouse management systems can be integrated with transportation management platforms to optimise dock scheduling, labour allocation and inventory placement.

This integration creates a feedback loop of continuous improvement. Transportation planners can work with procurement teams to optimise supplier selection based on logistics costs and service levels. They can collaborate with production planners to time deliveries with manufacturing schedules, reducing inventory carrying costs and improving cash flow.

5. Strategic flexibility and scalability

In addition to the above benefits, inbound transportation management provides strategic flexibility essential for businesses facing dynamic environments. It becomes increasingly valuable as your business grows and markets evolve. With adequate control, it's easier to quickly adapt to changing supplier bases, enter new markets or respond to disruptions without being constrained by supplier transportation capabilities.

Because you can make decisions with clear information rather than making decisions in isolation, it often opens up more supply chain opportunities, like nearshoring, supplier diversification and omnichannel distribution.

The inbound advantage in a volatile world

A robust inbound transportation management programme means you're not just reacting to market cycles, you're building a fundamentally more resilient and adaptable supply chain against whatever comes next—from pandemics to trade policy shifts.

Illustration of LTL consolidation

How to start an inbound programme

Either you or your suppliers are managing your inbound process today.

- If your suppliers select the carriers, negotiate the rates and pay the transportation charges, you are paying a combined fee for both the transportation and the product. The first step is to own the inbound transportation event.

Consider terms of sale and current freight allowances before creating an inbound programme. This may mean renegotiating contracts with vendors and breaking out transportation and purchasing costs within your systems. But it is often worth the effort. - If you currently own the transportation event, you have already delineated between the cost of transportation and the cost of goods. Now you're ready to further enhance your inbound management by improving business processes.

For greater supply chain performance and cost control, you'll need to put proactive processes and visibility in place to ensure that you have the right product at the right location at the right time.

What's involved in a good inbound logistics programme?

With a good inbound programme, you'll have a better understanding of the true cost of goods and transportation rates. A solid inbound programme allows you to:

- Monitor every inbound item in real time

- Review vendor and supplier business processes

- Map your own internal buyer/purchasing processes

- Consolidate deliveries and optimise loads and modes

- Monitor vendor deliveries to verify orders are delivering on time

- Report on compliance levels of vendors and supply chain performance

- Receive advance notice of late deliveries to change production schedules

- Change terms of sale and study freight allowances you are currently being offered

- Gain visibility to pending, complete and delivered inbound orders through a single data repository

- Review your business process changes and how they can yield real freight savings and increased transportation performance

Visibility and a proactive approach to managing an inbound programme

The next step—often the most overlooked—is to proactively manage your suppliers. This involves utilising business processes and visibility to identify issues in advance. Managing and auditing against your business processes can be done through available technology or through a service provider.

Technology gives all parties visibility to orders and expected arrival dates. When you have visibility to inbound orders from all your suppliers and apply optimisation rationale, individual orders can be grouped across facilities and multiple deliveries going to the same origin/destination pair over several days can be identified.

Using transportation management software (TMS), you can consolidate and ship using the most cost-effective mode and proactively monitor the deliveries in transit. As carrier and supplier compliance data is collected and analysed, you'll gain new insights for driving efficiency.

Without visibility to inbound freight and processes, it is difficult to identify and influence the process gaps that cause variability in your supply chain. Often, there isn't much wiggle room for late deliveries of critical materials. With delivery visibility, you can confirm that a delivery does, in fact, need to be expedited and in that event, you can choose the most efficient service for the requirements. The reasons for expediting the load can be captured and analysed to minimise the risk in the future.

Or perhaps you discover you're missing an item a few days before it's needed. The product was ordered, but did it deliver? When? Will it arrive on time? Where is it? Is it headed to the right facility? Is your service consistent enough to be sure?

Without visibility, it will take many hours and phone calls to get the answers. If the product arrives on time, everything can proceed as planned. But if the item you're waiting for doesn't arrive, you may not know it until it's too late to change tactics until the missing SKU arrives. The result can be overstaffing, understaffing and confusion at the dock where the product was to be received. This scenario has both cost and service implications.

How can you avoid overstaffing, understaffing and dock confusion?

- Order dates

- Mode shifting

- Actual pickups and deliveries

- Load tenders when freight is booked

- Status updates from the drivers in transit

- Deviations from your plans well in advance

- Vendor commitments for pickup and delivery

Intellectual capital and customisation

A third party logistics provider (3PL) can guide you to a well-managed inbound programme. They have systems that deliver proactive information and provide a greater certainty of uninterrupted processes, at little or no cost to you. In addition to the systems, they have supply chain professionals with practical experience with inbound logistics programmes.

Programmes can be customised by using best practices to meet your business needs. Frequently, this includes working with vendors in advance to determine whether freight is ready for pickup. If the freight is ready, the provider will schedule a vehicle to pick up the freight and give you a delivery date.

If the freight isn't ready as expected, your provider can note that in the system, triggering a notification to you well before your critical receipt window. That kind of proactive behaviour enables you to work with the vendor to expedite delivery or to switch to a different product/SKU until the missing part arrives. With proactive delivery information and greater certainty of strategies being executed as planned, you can save money and time.

Beyond general programme management, advanced inbound transportation solutions often incorporate item-level visibility and control, allowing for more granular management of your inbound supply chain. This can include:

- Real-time visibility: Gain comprehensive insight into your inbound deliveries with detailed, item-level tracking and customised alerts.

- Purchase order (PO) management: Transform purchase order demand into a comprehensive transportation plan.

- Supply chain design and optimisation: Collaborate with supply chain engineering experts to optimise various aspects of your inbound network.

- Inventory optimisation: Achieve precise SKU-level control over your inventory to align inventory strategy with both service and cost objectives.

Discover more opportunities in inbound logistics

This guide presents a few of the early decisions required to begin an inbound logistics programme. You can strengthen your programme by moving beyond the basics and employing additional inbound practices:

- Compliance

- Audit processes

- Inventory strategies

- Economic order quantities

- Reporting strategies and metrics

A qualified service provider can help you to choose and execute the practices that will best enhance your inbound programme.

- Common inbound logistics gaps

- Areas inbound management adds value

- Start a strategic inbound programme

- Proactively managing inbound freight

- Intellectual capital & customisation

- More opportunities in inbound logistics

http://www.chrobinson.nz/en-gb/chrglobal/resources/resource-center/guides/inbound-logistics/